Increase your plant efficiency by improving your process analyzer reliability

Increase your plant efficiency by improving your process analyzer reliability

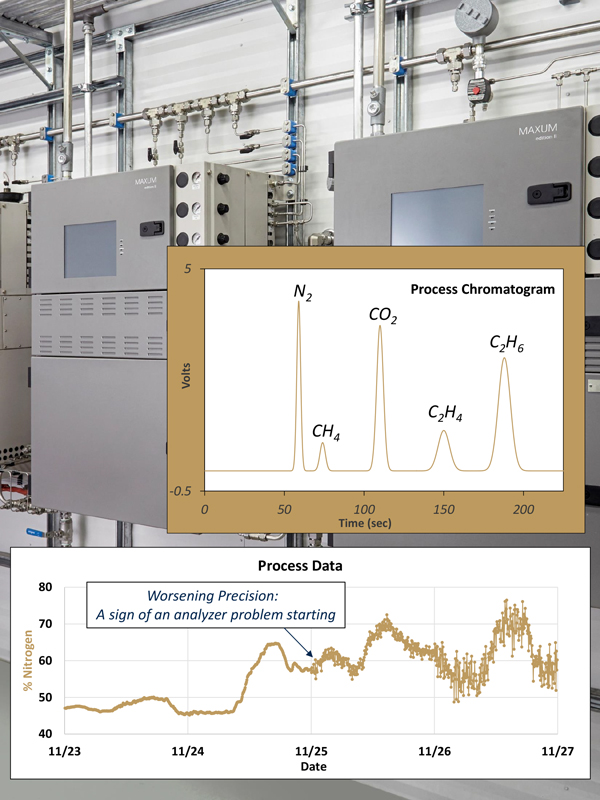

Investing in solutions to improve the reliability and performance of your process gas chromatographs (process GCs) makes good business sense. Process GCs are expensive to install and maintain, so it’s important to ensure that you are extracting full value from them by ensuring their accuracy and reliability.

A malfunctioning process GC can lead to hundreds of thousands of dollars in business losses and consume valuable resources as staff attempt to compensate by doubling up on other testing measures. Faulty data can lead to product and process streams that are out-of-spec, damaged catalysts, excessive utility usage, failure to comply with environmental regulations, industrial hygiene hazards, and plant safety issues.

Accurate, repeatable and reliable measurements are the key to obtaining optimal results in your process. Peak Performance can help you achieve the results you need, with expert technical support and solutions from one of the industry’s most experienced process GC experts, including:

- Performance evaluation of all process GCs in the plant

- Improvements to process analyzer data quality and reliability

- Design recommendations for process analyzer validation systems

- Optimization of process GC performance

- Process GC troubleshooting

- Detection of problems in analyzer sample systems

- Technical support for analyzer maintenance technicians

Your process GC’s reliability can be restored and improved with expert help

At Peak Performance, we know that the historic poor performance of process GCs in some plants has caused some plant leaders and chemical engineers to lose trust in – and stop relying on – the data from their analyzers. Peak Performance can help to restore your trust by identifying and fixing the root cause of your process GCs’ underperformance, and then setting up validation systems to ensure their reliability for the future.

As a Process Analyzer Reliability Specialist and Analytical Chemist, Peak Performance’s R. Aaron Eidt has decades of industrial analytical experience in both process and laboratory gas chromatography. From his Vancouver-area office, he offers remote and on-site technical support, and consulting services to clients in the chemical, petrochemical, and oil and gas industries across North America and overseas.

Aaron’s skill set, education, and experience allow him to troubleshoot a large number of process GC problems remotely by studying and analyzing the chromatograms of both your process samples and reference materials, and working with your on-site analyzer maintenance technicians. He is able to quickly and accurately diagnose whether the problem is with the sample system, the GC method, the GC hardware, or elsewhere, and make recommendations to resolve the problem.

Analyzer validation:

The quality of your operational decision-making relies on the quality of your data. To ensure your process GC is producing accurate data, it is necessary to have a validation system that will regularly assess your process GC data and generate an alarm if the result is inaccurate. Peak Performance can provide design recommendations and technical support to help you put a suitable system in place.

Analyzer modification:

With years of experience designing and troubleshooting process GCs, we can help your team learn to perform the minor modifications to the GC method that are frequently required to keep a process GC operating properly. If warranted, we can also make recommendations for major modifications to the GC method itself for improved performance.

Design issues:

Occasionally, and for a range of reasons, a GC method or its sample system has design issues, or perhaps the analysis requirements have changed since it was installed. In such instances, we can make recommendations for resolving the problem, which can otherwise plague an analyzer’s performance for years.

Process Gas Chromatograph Evaluation Service:

An overall evaluation is a cost-effective first step to determine whether your plant’s process GCs are performing optimally, and if they are producing data that is sufficiently accurate and precise. It gives you the information you need to move forward to:

- Restore the reliability of your analyzer data

- Maximize the utilization of your equipment

- Create a proactive maintenance plan for sustained performance

With the help of your maintenance technician, we examine your installed process GCs one-by-one to assess their data quality, their validation system effectiveness and suitability, and the health of their chromatographic separations. Any missing components to your process GC’s data quality program are identified, unaddressed maintenance issues are highlighted, and much more. At the end of the evaluation, we provide you with a clear, written summary that identifies any problems and recommends solutions for moving forward.

Peak Performance technical support and consulting offers a cost-effective solution

Peak Performance’s solutions give you access to one of the industry’s most experienced process GC experts, without the cost of retaining a specialist on staff. Analyzer downtime and errors are reduced, and remote troubleshooting and technical support services save thousands of dollars in travel costs.

Need help improving the reliability and performance of your process GCs? Please contact R. Aaron Eidt at Peak Performance Analytical Consulting.